2017年5月5日星期五

2017年5月4日星期四

Welding Tips & Spot Welding Electrode Tips

Welding Tips Specification:

Product Name:Welding Tips & Spot Welding Electrode Tips

Welding Tips Material:CuCrZr,CuCr,Al2O3Cu (optional)

Copper Class: RWMA Class 2,ISO5182-1991,ASTM C18150,DIN 17666 2.1293, CW106C,UNS.C18150, SAE J461,463;

Electrode Tips Application:Spot Welding Machine,IT Gun Spot Welding,Robotic Gun Spot Welding

Electrode Tips Shapes:Various Shapes,Special size can design as your requirements

Contact Us:

Welding Electrode Tips Size Drawing:

Spot Welding Electrode Tips Size Drawing:

Nut Electrode for Nut Welding

Nut Electrode for Nut Welding

Nut Electrode Introduction:

Product Name: Electrode for Nut Welding

Nut Electrode Material: Copper

Nut Electrode Application:Nut Welding Machine

Nut Shapes:Various Shapes,Special size can design as your requirements

Nut Electrode Drawing: (Material: CuCrZr)

Bolt Welding Electrode

Bolt Welding Electrode Tips Introduction:

Product Name: Bolt Welding Electrode

Bolt Electrode Material: CuCrZr Copper

Bolt Electrode Application:Bolt Welding

Electrode Shapes:Various Shapes,Special size can design as your requirements

Bolt Electrode (Material:CuCrZr + KCF)

Spot Welding Electrodes & Welding Electrodes Material

Spot Welding Electrodes Specification:

Product Name:Spot Welding Electrodes & Welding Electrodes Material

Welding Electrodes Material:CuCrZr,CuCr,Al2O3Cu (optional)

Copper Class: RWMA Class 2,ISO5182-1991,ASTM C18150,DIN 17666 2.1293, CW106C,UNS.C18150, SAE J461,463;

Welding Electrode Application:Spot Welding Machine,IT Gun Spot Welding,Robotic Gun Spot Welding

Spot Welding Electrodes Size Drawing:

Spot Welder Electrodes Arm

Spot Welder Electrodes Arm Specifications:

Product Name: Electrodes Arm

Application for Spot Welder,IT Gun Spot Welding,Robotic Spot Welding

Material:CuCrZr Copper

Universal Electrode for Resistance Welding

Universal Electrode for Resistance Welding

Product Name:Universal Electrode

Material:CuCrZr Copper

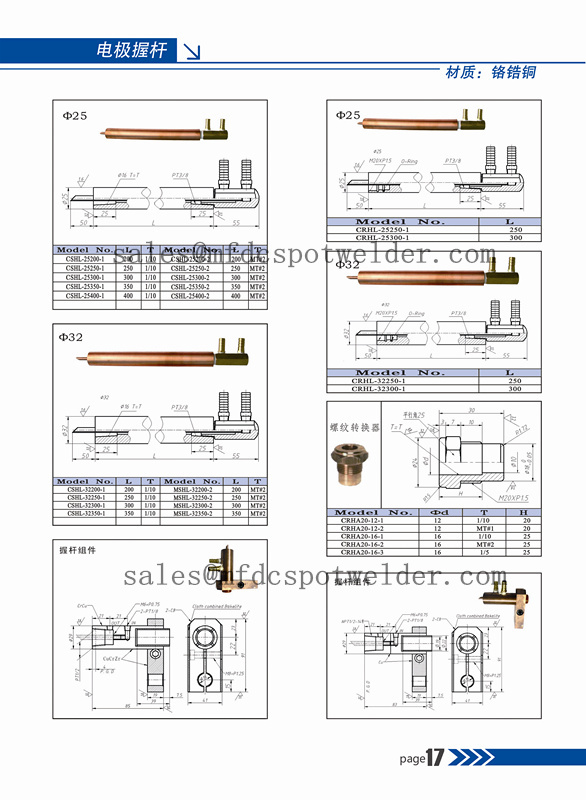

Spot Welding Electrode Holder

Spot Welding Electrode Holder Introduction:

Product Name: Spot Welding Electrode Holder

Electrode holder material: CuCrZr copper

Electrode holder application:Spot welding machine

Contact Us:

Straight Electrode Holders (Material:CuCrZr)

L type Electrode Holder (Material: BSBM)

Resistance Welding Electrodes

We supply all kinds of resistance welding electrodes,electrode caps.It is typical used on spot welding.

Resistance Welding Electrodes Specifications:

We design and manufacture resistance welding electrode,spot welding electrode,electrode caps,spot welding electrode holder...

Product Name:Resistance Welding Electrodes

Electrode Material:CuCrZr,CuCr,Al2O3Cu (optional)

Copper Class: RWMA Class 2,ISO5182-1991,ASTM C18150,DIN 17666 2.1293, CW106C,UNS.C18150, SAE J461,463;

Application for Spot Welder

Product Name:Resistance Welding Electrodes

Electrode Material:CuCrZr,CuCr,Al2O3Cu (optional)

Copper Class: RWMA Class 2,ISO5182-1991,ASTM C18150,DIN 17666 2.1293, CW106C,UNS.C18150, SAE J461,463;

Application for Spot Welder

Resistance Welding Electrodes Drawing:

Threaded Electrode Adapters

We design and manufacture threaded electrode adapter,welding electrode,electrode caps,cap tips.

Welding Adapters Introduction:

Product Name: Welding Adapters,Screwed Adapter

Electrode Adapter Type:Cone adapter and Screwed adapter

Electrode Adapter Material: Brass Copper,beryllium copper

Adapter Size:12mm-22mm (special size,please contact our sales)

Electrode Adapter Appliation:Projection welding,nut welding,bolt welding

Threaded Electrode Adapters (Material: CuCrZr)

Welding Adapters Introduction:

Product Name: Welding Adapters,Screwed Adapter

Electrode Adapter Type:Cone adapter and Screwed adapter

Electrode Adapter Material: Brass Copper,beryllium copper

Adapter Size:12mm-22mm (special size,please contact our sales)

Electrode Adapter Appliation:Projection welding,nut welding,bolt welding

Cone Adapters (Material: Brass Copper)

PT Threaded Electrode Adapters (Material: Brass Copper,Beryllium Copper)

Threaded Electrode Adapters (Material:Brass Copper,Beryllium Copper)

Seam Welding Wheel For Seam Welder

We design and manufacture seam welding wheel,spot welding cap tips,electrode cap tips.

Seam Welding Wheel Specifications:

Product Name:Seam Welding Wheel

Welding Wheel Material:CuCrZr Copper

Seam Welding Wheel Application:Seam Welder

Seam Welding Wheel Shape:Various Shapes (Customize according to client’s drawing)

Manual Electrode Tip Dresser

We supply manual tip dresser,spot welding tip dresser,cutter blade,holder...

Manual Electrode Tip Dresser

Pneumatic Tip Dresser & Cutter Blade

We supply pneumatic tip dresser,manual tip dresser,cutter balde,holder...

Pneumatic Tip Dresser Technical Specifications:

Model:CDY-1 tips dresser for spot welding

Product Name:Spot welding tip dresser

Power:Compressed Air

Electrode Diameter:12mm-18mm

RPM:1300

Weight:1.8Kg

Spot welding Tip Dresser Features:

Small,light and simple to operate

Center,Autosearch

Easy to change the holder and blade

Low air consumption

Tip Dresser Cutter Blade Specifications (Material:SKH)

Projection Welding KCF Guide Pins

Projection Welding KCF Guide Pins

Guide Pins Material: KCF,AL2O3,ZrO2,Si3N4

Product Name:Projection Welding guide Pins,welding guide pin

Projection Welding KCF Guide Pins Size Drawing:

Projection KCF Weld Pins & Locating Pins

Projection Weld Pins & Locating Pins

Weld Pins Material: KCF,AL2O3,ZrO2,Si3N4

Product Name:Weld Pins for Projection Welding,Locating Pins

Guide Pins,Locating Pins Size Drawing:

KCF Insulation Guide Pins For Projection Welding

KCF Insulation Guide Pins For Projection Welding Technical Specification

Guide Pins Material: KCF

Guide Pins Diameter:M4,M5,M6,M8,M10,M12

KCF Guide Pins Advantage:

Good insulation performance

Excellent wear resistance ability

High temperature anti-oxidation performance

Good heat shock performance

What is KCF Guide Pins?

KCF material is a special metal material,the main metal elements are iron,chromium,lead,mercury,PBB,PBDE,etc.Through special heat treatment process and process temperature range of 1000-1500 degree adjustment,the surface can generate a layer of 8-10μ thick high-quality insulation layer,the insulation layer and the alloy matrix has a good ability to combine.So that the material takes into account the good wear resistance and high insulation resistance.The material in the mechanical processing after formation of a variety of parts,after cleaning and heat treatment with insulation,wear and anti-oxidation of the three functions of the product.This material is mainly used in resistance welding equipment.

We generally use ceramic guide pins as a welding nut positioning pin, but because of the toughness of ceramics is poor, fragile, so now generally use KCF as a material positioning pin instead of ceramic, because of its main metal, toughness and crack are better than the ceramic, life compared to industrial ceramics is more durable, but the only bad is the relatively high price, its performance is also several times higher than the ceramic guide pins.

Contact Us:

KCF Insulation Guide Pins Size Drawing:

Straight Shanks & Bent Shanks

Product Name:Straight shank & Bent electrode shanks

Welding Straight Shank material: CuCrZr copper

Welding Straight Shank Application:Spot welding machine,IT gun spot welding,Robotic gun welding

Contact Us:

Spot Welding Straight Shanks (Material:CuCrZr)

Weld Force Tester (Handheld type)

Weld Force Tester (Handheld type)

YC Weld Force Tester Features:

A wide range of measurements (from 0.20daN to 931daN) can be accomplished simply by replacing the sensors.

Automatic sensor detection

The measurement unit can be switched between kg and daN. (1daN = 10N)

Large clear LCD.

One-touch zero calibration.

The panel sheet resists dust and oil mist.

Contact Us:

YC Weld Force Tester Specification:

| Model | YC Weld Force Tester |

|---|---|

| Accuracy level | 0.5% FS |

| Measuring range(Different force receiver optional) | 0-500KG |

| 0-1000KG | |

| 0-2000KG | |

| 0-5000KG | |

| 0-10000KG | |

| Max. Overload capacity | 120% |

| Preheat settling time | 1 min |

| Conditions | 0-40°C?<=80%RH |

| Size | 160*70*29mm |

| Power Supply | 3.6VDC,3pcs nickel cadmium batteries |

| Weight | 0.5KG |

PMC Weld Checker (desk-top type)

PMC-53A Weld Checker (desk-top type)

Highly functional and highly precise weld monitor & weld checker for various weld current waveforms.

Cyclical and accurate display of the welding time for AC inverter welding.

Light and compact body. Fast measuring speed, and easy installation.

Simple “turn” and “press” operations with a single button.

The measuring unit from “ms” or “Cycle” on measuring welding time can be selected.

Communication facility is equipped on standard.

Measured values can be transferred to a PC and the evaluation criteria can be changed from the PC. RS232C and RS-485 are equipped on standard

Contact Us:

PMC-53A Weld Checker Specification:

PMC-53A Weld Checker

| Model | PMC-53A | ||||||

|---|---|---|---|---|---|---|---|

| Measurement | Current | Measuring range | 0.010 – 0.199kA (Only when 10x sensitivity coil used) 0.100 – 1.999kA 1.00 – 19.99kA 10.0 – 199.9kA | ||||

| Measured value | The peak value of the total welding or arithmetic mean RMS in the measured range can be measured. | ||||||

| Display | 4-digit digital display (7-segment LED) | ||||||

| Measuring range setting | Start | AC | 000-500 cycles (31 conditions) | DC | 0000 – 2000ms (31 conditions) | ||

| End | (Supports 50- 250 Hz) | 0.50 – 25.00ms(31 condition) | |||||

| Measurement accuracy | RMS ± (2%rdg + 4dgt) *1, PEAK ± (2%rdg + 10dgt) | ||||||

| Detection method | Toroidal coil | ||||||

| Time | Welding-cycle / Pulsewidth | Measuring range | The maximum measurement duration is 2 seconds. Single-phase AC 0.5-100 cycles (50 Hz)/0.5-120 cycles (60 Hz) | ||||

| AC inverter type 0.5 – 500 max. cycle (depending on welding current frequency) or 0.50 – 2000ms (until half time of IP for TH) | |||||||

| Display | 4-digit digital display (7-segment LED) | ||||||

| Detection method | Toroidal coil | ||||||

| Conduction angle | Measuring range | 30 – 180° Maximum conduction angle within welding time | |||||

| Detection method | Toroidal coil | ||||||

| Voltage | Measuring range | – | |||||

| Measured value | – | ||||||

| Display | – | ||||||

| Display | – | ||||||

| Measurement accuracy | – | ||||||

| Detection method | – | ||||||

| Current & voltage measurement value | RMS | Cycle display: Arithmetic mean RMS for each half cycle. “msec” display: Arithmetic mean RMS per each 1msec | |||||

| Transistor type: RMS from the start to the end. Capacitor type: RMS from the start of welding to the TH. | |||||||

| PEAK | Maximum PEAK during entire welding time | ||||||

| Pressurization | Measuring range | – | |||||

| Detection method | – | ||||||

| Monitoring | Welding current | Upper/lower limit 31 schedule setting. Setting range 0 to Maximum measurement range | |||||

| Welding time | Upper/lower limit 31 schedule setting. Setting range 0 to Maximum measurement range | ||||||

| Status alarm display | Each dedicated lamp for upper limit, lower limit and “in-rage” will show the status. | ||||||

| Status alarm signal | “GOOD”, “NG-H”, and “NG-L” semiconductor relay | ||||||

| Impulse setting | 0 – 9 (Sets the location for measuring pulsation welding.) | ||||||

| Counter | 99999 max. 5 digits | ||||||

| Printer | Option (BL2-58PN-MYT) | ||||||

| Print-out the following; the current welding time, evaluation result, schedule no., conduction angle and *ACS data counter value been measured and displayed. *All Cycle Schedule | |||||||

| Step up | 11 – 9 steps | ||||||

| Communications output | RS-232C/RS-485 The current, weld-time, evaluation results counter value and schedule data measured and display can be transfer in the communication facility. | ||||||

| Power requirements | Single-phase 100 – 240VAC ±10% (50/60Hz) or 24VDC ±10% | ||||||

| Mass | 1.9kg | ||||||

| Operating ambient temperature | 0 – 40°C | ||||||

| Power consumption | 112W max. | ||||||

订阅:

评论 (Atom)